As sustainability moves from trend to necessity, the global paper bag industry is experiencing rapid transformation. With the market expected to exceed $7 billion by 2025, businesses worldwide are shifting from single-use plastics to eco-conscious alternatives, making paper bags a great solution that aligns with both consumer expectations and environmental goals.

At the heart of this movement lies kraft paper, a durable, recyclable material made from long wood fibers that give paper bags their signature strength and earthy appeal. Modern manufacturing techniques now combine efficiency with responsibility to meet high-quality standards, using recycled pulp, water-saving processes, and biodegradable adhesives to create versatile packaging that’s as functional as it is sustainable.

At Itendee, we believe that the future of packaging lies in innovation rooted in responsibility. By understanding how paper bags are made and the technology driving their evolution, businesses can recognize them as an eco-friendly choice for various uses that benefit both brand and planet.

How Paper Bags Are Manufactured

The manufacturing of paper bags combines traditional papermaking techniques with modern automation to produce packaging that’s both strong and sustainable. From preparing raw materials to adding custom prints and handles, every step plays a vital role in creating the bags you see in retail, grocery, and luxury stores today.

1. Raw Material Preparation

It all begins with wood pulp or recycled paper fibers, which are cleaned and refined before being turned into kraft paper rolls. Kraft paper is valued for its high tensile strength and natural brown color, making it the foundation for durable and eco-friendly bags.

2. Paper Roll Processing & Cutting

Once the kraft paper is ready, large rolls are fed into cutting machines that slice them into specific widths and lengths. These measurements depend on the bag’s size and purpose — whether it’s a small boutique bag or a heavy grocery sack. Precision at this stage ensures minimal waste and consistent results.

3. Printing & Branding Stage

Before shaping the bag, it’s time for branding. Using flexographic or offset printing, logos, colors, and designs are added directly onto the kraft paper. At Itendee, we use water-based, non-toxic inks, making the bags safe, vibrant, and 100% recyclable, which is especially important for brands targeting families with kids. This makes them ideal for brands that value both aesthetics and sustainability.

4. Bag Formation

This is where flat paper turns into a functional bag. Through automated machines, the paper is folded, glued, and tubed into its final shape. Gussets (side folds) and a flat bottom are added to give structure and volume, ensuring the bag can hold various weights without tearing.

5. Handle Attachment (if needed)

For carry bags, handles are attached, typically made of twisted paper, flat strips, or rope. Each handle type is designed for comfort and load-bearing strength, depending on how the bag will be used.

6. Quality Assurance & Packing

Every finished bag is tested for strength, print quality, and durability. Once approved, they’re bundled, packed, and shipped for use in retail, food, or promotional packaging.

💡 AtItendee, we follow this same meticulous process, from sourcing responsibly to printing sustainably, ensuring every paper bag you choose meets both quality and environmental standards.

Kraft Paper & Brown Paper Bags

Kraft paper is the backbone of modern paper bag manufacturing. Known for its strength, flexibility, and natural texture, it has become the global standard for sustainable packaging. Understanding what Kraft paper is, and why it’s naturally brown helps explain why it dominates grocery, retail, and eco-conscious product packaging today, especially in contrast to plastic bags.

Definition of Kraft Paper Bags

Kraft paper is a strong, unbleached type of paper made through the “kraft process,” where wood pulp is treated to retain long cellulose fibers. These long fibers give kraft paper its high tear resistance, elasticity, and durability, making it ideal for heavy-duty applications. Unlike regular paper, kraft is tougher, breathable, and can easily handle moisture and weight without tearing.

Why Most Grocery/Retail Paper Bags Are Brown (Kraft)

The natural brown color of kraft paper, which is its natural color, comes from its unbleached wood fibers, meaning no harsh chemicals are used in the process., meaning no harsh chemicals are used in the process. This makes it both eco-friendly and cost-effective to produce. Retailers and grocery stores prefer brown kraft bags because they represent authenticity, strength, and environmental responsibility, values that today’s customers connect with sustainable brands.

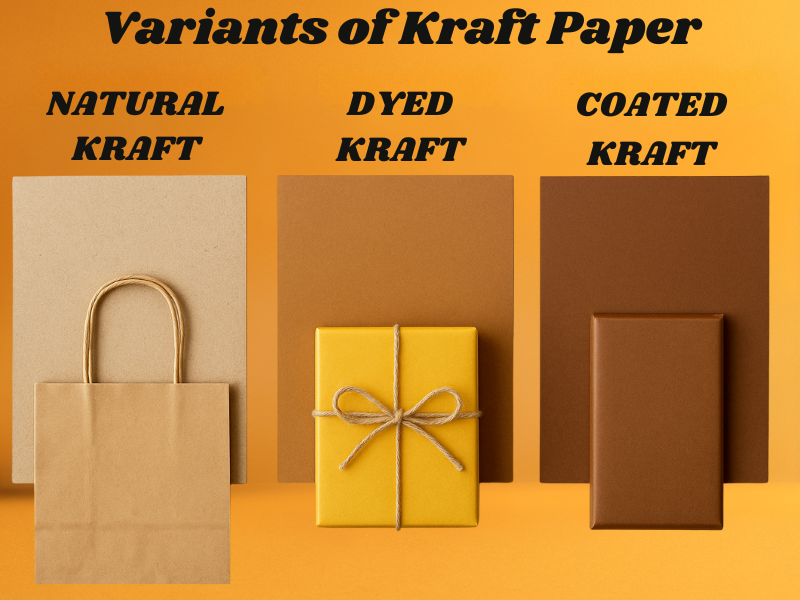

Variants of Kraft Paper

While natural brown kraft is the most common, manufacturers often produce several variants to match different needs:

- Natural Kraft: Unbleached, recyclable, and the most sustainable option.

- Dyed Kraft: Colored versions made for branding or premium packaging.

- Coated Kraft: Has a thin layer of gloss or matte coating for added water resistance and a refined look, often used in luxury packaging.

💡 At Itendee, we source and customize kraft paper bags in all variants, from rustic natural kraft for grocery use to coated and printed options for high-end retail, ensuring your packaging reflects both strength and sustainability.

Key Properties of Paper Bags

Paper bags may seem simple, but their performance depends on several technical properties that make them strong, reliable, and environmentally responsible. From fiber strength to print quality, every element plays a role in ensuring that a paper bag not only looks good but also performs effectively in everyday use.

Strength & Load Capacity

The strength of a paper bag comes from the length of its fibers and the paper’s weight (GSM – grams per square meter). Longer fibers mean greater tensile strength, allowing kraft bags to carry heavy items without tearing. For example, high-GSM kraft paper is often used for grocery or retail bags that handle weighty goods.

Breathability & Venting

Unlike plastic, paper is naturally breathable. This allows air to circulate and prevents moisture build-up, making paper bags ideal for fresh produce, baked goods, or warm foods. This property also helps reduce condensation and spoilage, ensuring products stay fresher longer.

Eco Attributes

Paper bags stand out for their biodegradability, compostability, and recyclability. Made from renewable fibers, they break down naturally and can be reprocessed into new paper products multiple times. When sourced responsibly, kraft paper supports a closed-loop recycling system, helping reduce carbon footprint and landfill waste through innovative packaging solutions.

Print Compatibility

The smooth surface of kraft paper makes it excellent for flexographic and offset printing, allowing vibrant colors, clean logos, and sharp branding. Its high ink adherence ensures designs remain durable even during handling, an advantage for retail packaging and promotional bags.

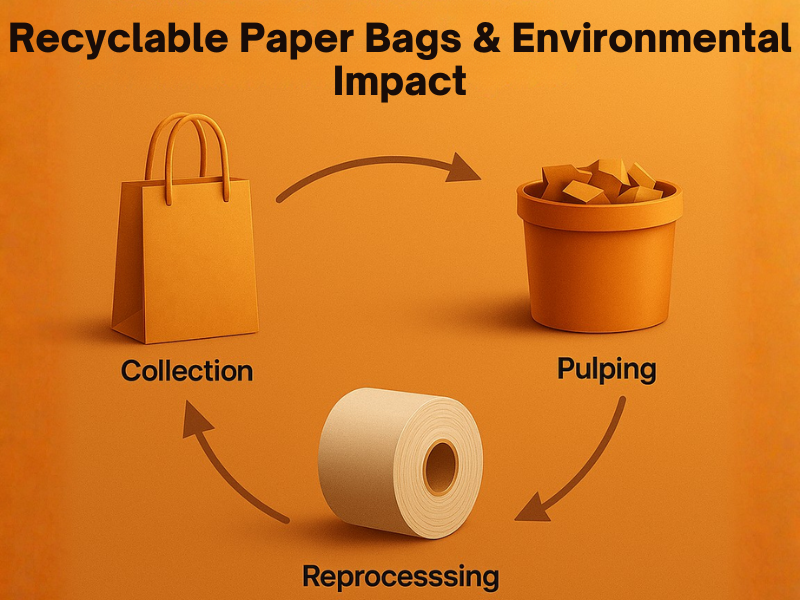

Recyclable Paper Bags & Environmental Impact

One of the strongest advantages of paper bags lies in their end-of-life value, they don’t just serve as packaging but as part of a circular, renewable system. When designed right, paper bags can be collected, pulped, and reborn into new products, reducing landfill pressure and supporting a cleaner planet.

What Makes a Paper Bag Recyclable

A paper bag is considered fully recyclable when it’s made from clean, uncoated kraft paper without plastic or wax layers. Bags that use water-based inks and adhesives are easier to recycle and maintain fiber integrity during reprocessing. Contamination from food or plastic films, however, can reduce recyclability, which is why clean disposal matters.

Recycling Process: Collection, Pulping & Reprocessing

Used paper bags are collected, sorted, and sent to recycling plants where they are pulped in water to separate the fibers. The pulp is then cleaned, refined, and pressed into new paper rolls, often reused for packaging or printing materials. Each fiber can typically be recycled four to six times before it loses strength, extending the material’s useful life.

Paper vs. Plastic Recyclability

While both materials can technically be recycled, paper bags are easier to reprocess and decompose naturally. Plastic recycling requires complex sorting and often results in downcycled products. In contrast, paper maintains its circular value and can return to the production cycle with minimal chemical treatment.

Role in Reducing Landfill Waste & Carbon Footprint

Switching from plastic to paper can reduce carbon emissions by up to 60%, especially when made from recycled content. Since paper bags are biodegradable and compostable, they naturally decompose without releasing harmful microplastics. When paired with responsible sourcing and consumer purchase decisions, they contribute to a lower overall carbon footprint across supply chains and save companies money.

💡At Itendee, we prioritize 100% recyclable kraft paper and sustainable printing methods, ensuring every bag supports not only your brand but the environment it serves.

Comparison: Kraft Paper Bags vs Other Packaging Materials

| Feature | Kraft Paper Bags | Plastic Bags | Jute Bags | Fabric Bags (Cotton/Canvas) |

|---|---|---|---|---|

| Eco-Friendliness | Biodegradable, recyclable, and compostable | Non-biodegradable, polluting | Reusable, natural fiber | Reusable, but resource-intensive to produce |

| Strength & Load Capacity | Moderate to high (based on GSM) | High, but easily torn by sharp objects | Very high | Very high |

| Production Impact | Low, made from renewable or recycled fibers | Very high, petroleum-based | Moderate, requires cultivation and water | High, water- and energy-intensive |

| Cost Efficiency | Affordable and scalable | Very cheap, but environmentally costly | Higher cost due to weaving | Moderate to high |

| Reusability | 2–3 times (depends on quality) | Single-use | 50+ uses | 30–50 uses |

| Decomposition Time | 2–6 weeks | Up to 500 years | 1–2 years (natural fibers) | 5+ months |

| Branding & Print Quality | Excellent, compatible with water-based inks | Limited, often requires lamination | Moderate, limited surface smoothness | Good, fabric texture affects clarity |

| Best Use Case | Retail, grocery, and food packaging | Short-term, disposable packaging | Bulk, promotional, or heavy goods | Premium retail, fashion, or reusable campaigns |

Innovations in Paper Bag Manufacturing (2025 and Beyond)

The paper bag industry is evolving fast, blending sustainability with smart technology. Modern innovations are reshaping how kraft paper bags are produced, making them stronger, cleaner, and more resource-efficient than ever.

Automation in Production

Advanced automated machines now handle every step, from cutting and folding to gluing and handle attachment, with precision and speed. This reduces human error, minimizes material waste, and ensures consistent quality even in high-volume production runs.

AI-Based Quality Control

Artificial Intelligence has entered the factory floor. AI-driven sensors and cameras inspect every bag in real time, identifying even the smallest printing misalignments or bonding flaws. This technology not only enhances quality but also helps manufacturers predict maintenance needs and reduce downtime.

Biodegradable Coatings & Adhesives

To meet global sustainability goals, manufacturers are replacing plastic or wax coatings with bio-based, compostable coatings derived from natural polymers like starch and cellulose. Similarly, water-based glues are being adopted to ensure that every component of the bag, from surface to seal, remains recyclable and biodegradable.

Recycled Pulp Optimization

New pulp treatment methods allow kraft paper to be made with a higher percentage of recycled fibers without compromising strength. These innovations extend fiber life, conserve energy, and reduce deforestation, contributing directly to a circular packaging economy.

💡At Itendee, we stay ahead of these advancements, integrating automation, AI-driven inspection, and sustainable materials into every stage of production. The result? Paper bags that deliver superior quality and align with the green standards of tomorrow.

Frequently Asked Questions (FAQ) – Paper Bag Manufacturing & Kraft Properties

1. How are paper bags made step-by-step?

Paper bags are made through a structured process starting from pulping raw or recycled fibers, converting them into kraft paper rolls, then cutting, printing, folding, gluing, and finishing to form durable, branded bags ready for use.

2. Why is Kraft paper so commonly used for bags?

Kraft paper is preferred because it’s strong, affordable, and naturally brown, produced without harsh chemicals. Its long wood fibers give it excellent tear resistance and flexibility, making it a reasonable choice for everything from groceries to retail packaging.

3. Are paper bags always recyclable?

Yes, as long as they are uncoated, uncontaminated, and printed with water-based inks, kraft paper bags can be recycled multiple times, helping maintain a sustainable packaging loop.

4. What are the main properties of a good paper bag?

A quality paper bag offers durability, printability, breathability, and eco-friendliness. It should carry weight effectively, support clear branding, and decompose naturally after disposal.

5. What differentiates brown paper bags from others?

Brown paper bags are typically made from unbleached kraft paper, giving them their natural, earthy color. This makes them stronger, more eco-conscious, and more cost-efficient than bleached or coated alternatives.

Conclusion

Paper bag manufacturing is a sophisticated blend of engineering, material science, and sustainability. By using kraft paper, manufacturers produce bags that are strong, printable, and fully recyclable, meeting both functional and environmental goals. With innovations in pulp processing, eco-friendly inks, and renewable sourcing, paper bags continue to evolve as a smarter alternative to plastic, balancing performance with planet-friendly design.

Looking to make your packaging both durable and eco-conscious?

At Itendee, we craft custom kraft paper bags designed for grocery, retail, and branding needs, all with recyclable materials and high-quality printing options.

💬 Request a quote today to upgrade your packaging sustainably and showcase your brand’s commitment to a cleaner future.