Introduction

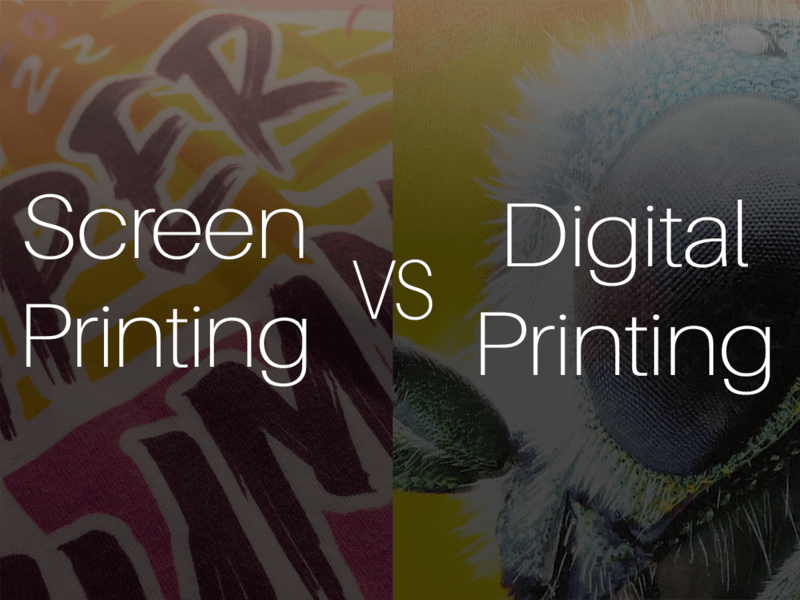

When looking to customize textiles for clothing or bags, the most important thing to decide between is choosing the right printing method, whether to go for screen printing or head for digital printing. These two methods offer their own unique benefits, and selecting the right option is based on factors like design complexity, fabric style, and the quality needed, followed by your overall budget.

Whether you are looking for bulk production in consistent design or you want to have individual pieces customized for your small-sized business, understanding the difference between screen printing and digital printing is a must. The guide below will offer you an insight into both of these methods in detail. So, let’s take a look.

What Is Screen Printing?

Screen printing, also called silkscreen printing, is a method of transferring a design on a surface using mesh screens, ink, and a squeegee. It is commonly used in apparel production but is also applicable to wood, plastic, metal, and paper.

How Does the Process of Screen Printing Work?

The screen printing process requires a screen or a stencil that is created according to the design in the form of a fine mesh screen. The screen comprises polyester, which has a coating of light-sensitive emulsion. The design is placed on the top of the screen, and it is then subjected to light. The areas that are exposed tend to get hard, whereas the unexposed areas are washed away, leaving space for ink to pass.

As soon as the screen is ready, it is placed on the fabric or material over which printing is required. The ink is poured on the top, and a squeegee is pulled across the screen, allowing ink to pass through the open areas of mesh on the fabric. Every color in the design needs a different screen, and therefore, it is a labor-intensive process.

Suitable for High Volume Orders

Screen printing involves a detailed setup process, especially if you have designs with multiple colors. Hence, to attain cost-effectiveness, you can print in large quantities, as once the screen is prepared, the process of printing becomes efficient. Screen printing is suitable for bulk custom orders like branded merchandise, fashion products, uniforms, and event giveaways.

Durable Prints with Vibrant Colors

The biggest strength of screen printing is the durability and quality of the print. The inks are thick and allow them to sit on the fabric rather than soaking into it. Screen-printed designs create bold and bright colors even if the fabrics are dark. These prints are even resistant to fading, peeling, and cracking despite multiple washes.

Design Limitations

Screen printing excels at all designs; still, despite the graphics, the screen printing method is not suitable for creating designs that comprise precise details, photographs, and gradients, as every color needs exact alignment and a separate screen.

Hence, the process can become complicated and expensive when multiple colors and complex designs are involved. Also, any change in the design requires recreating the screen.

What Is the Digital Printing Process (DTG)?

Digital printing, also called direct-to-garment printing, is a modern technique for printing designs with full colors on fabric directly through inkjet technology. Unlike traditional screen printing, digital printing eliminates the need for stencils and screens.

Digital printing works like a desktop printer, where water-based inks are sprayed on the garments directly with ease and precision. It allows the creation of vibrant and high-resolution designs with very little setup time.

How does the Process work?

The digital printing method starts by first placing garments on a flat plate that is inside the printer. The material usually opted for in digital printing is cotton.

Before printing, the garment can be treated with a solution to make the ink appear vibrant and well-adhered to the fabric. The printer then directly creates the design on the garment through layers using the tiny ink droplets that are controlled by a digital program in a digital file.

Since the digital printing method uses digital files of images, the need for separate colors and different stencils is not present, and hence the process is more flexible and quicker. Digital printing makes short-run orders a breeze due to its flexibility of on-demand production.

Suitable for Complex and Photographic Designs

Direct-to-garment printing seamlessly works in creating finely detailed images through flatbed printing. It can produce smooth gradients, complex textures, and even photographic artwork.

As the printer uses thousands of tiny ink droplets, it can produce subtle color transitions and fine lines with high accuracy. Hence, creating the intricate designs that are very detailed for screen printing can easily be created through digital printing methods.

Suitable for Custom Orders and Small Batches

Manufacturers do not charge too much for DTG because the setup is straightforward for digital printing compared to screen printing. Hence, this process is quite suitable for custom and small orders. So, whether you are opting for personalized t-shirts or you are trying new designs for your brand, you can make a small number of pieces without spending too much of your time and money.

This method of printing is also suitable for e-commerce businesses and print-on-demand platforms where flexibility and speed are essential.

Eco-Friendly and Soft Hand Feel

One of the significant benefits of digital printing is that it creates a very soft hand feel when finished perfectly. As the ink absorbs well into the fabric rather than just sitting on the top as in screen printing, the outcome is very smooth and breathable. It is highly suitable for light colored garments where the print is invisible to the touch.

Direct-to-garment printing also uses less ink and produces less waste, which makes it an environmentally friendly choice. Hence, when considering printing a few pieces at a time, it is quite feasible for the environment.

Side-by-Side Comparison between Printing Methods

| Feature | Screen Printing | Digital Printing (DTG) |

| Setup Cost | The initial setup cost is high, as every design needs a different stencil. | The setup cost is low, as you have to pay for the print only. |

| Best For | Suitable for simple designs in bulk. | Suitable for custom designs, even in small numbers of pieces. |

| Color Range | Limited colour range per run. | Unlimited colors are available for printing in one go. |

| Durability | Highly durable printing method | Durability is moderate, and it creates softer prints. |

| Turnaround Time | Takes a longer time due to the complex setup process. | Very quick printing method. |

| Cost per Unit (Bulk) | When printed in bulk, it is cost-effective. | High cost of production. |

| Ideal Applications | Suitable for uniforms, custom apparel, canvas shoes, etc. | Meant for personalized orders and custom t-shirts. |

When to Choose Which Method

Choosing between screen printing and digital printing is dependent on your requirements, and it also requires considering the volume of order, design complexity, turnaround time, and budget. Both screen printing and digital printing process have their own pros and cons depending on the use case.

Select Screen Printing When:

The following scenarios make screen printing a better option to choose:

Bulk Production Volume

Screen printing is highly cost-effective when the quantity grows. Once you have created screens, you can print thousands of garments quickly and economically. The cost of every unit decreases when the volume of production is high, which makes it suitable for manufacturing wholesale uniforms, apparel, marketing materials, and even canvas shoes.

Simple Designs with Limited Colors

If your design comprises bold shapes and text in one to three solid colors, then screen printing can be a good choice. Every color will need a separate screen and application. Simple designs make the process of setup faster and reduce the cost. Hence, when it comes to minimalist artwork or classic branding, screen printing can be a good choice.

Vibrant and Long Lasting Prints

Screen printing can create an opaque and thick layer of raised print, creating bold visuals with very bright neon colors that resist cracking and fading. It is durable for athletic and work wear. The print quality can even withstand repeated washing, and keeps visual impact a priority.

Select Digital Printing When:

Digital printing can be a suitable choice in the following cases.

Photo-Quality Full Color Prints

DTG printing has the capability to produce photographic ima, gradients, and designs that have multiple colors followed by intricate details. It can create your design at once without any excessive cost and time. If you have complex artwork that needs artistic and lifelike image quality, digitally printed designs can be a good choice.

Small Production Quantity with Quick Turnaround Time

Digital printing needs no screens, and therefore, the setup is minimal. Hence, for one-off prints and short runs, it can be a great choice. DTG also helps to create samples or test orders in no time. So, if you are looking to fulfill personalized orders for your last-minute projects, then DTG is a faster way with a better print quality.

Minimal Setup and Soft Fabric Feel

DTG ink soaks into the fabric, unlike screen printing, which sits on the top; hence, it helps to create a softer and natural look. Despite being absorbed in the fabric, there is no hassle of thinking about what if the shirt color bleeds. Also, digital printers use water-based inks, which produce less waste, and with a minimal setup, you can easily create small batches through an eco-friendly setup on the printing surface.

Choosing Screen vs Digital Print

When choosing between screen printing vs digital printing for your projects, it is important to understand various factors. Some of the considerations consist of order volume, colors, but apart from this, cost-effectiveness, environmental impact, and durability also have a role to play.

When is digital printing more cost-effective than screen printing?

Digital printing is more cost-effective than screen printing, especially if you have to work with small quantities. When your design comprises different colors, digital printing can be the first choice for most vendors.

Screen printing needs a time-consuming setup for every single color, whereas digital printing needs just a digital file and a printer. You don’t have to worry about the color separations and alignment issues, which helps to save labor costs and time.

You can consider an example where you need to print only a couple of shirts with colorful and intricate designs, then digital printing can be a better choice. However, it is cost-effective on a per-unit basis, but it requires high volumes to be economical. So, for a small product line or testing your design, DTG is better in terms of offering value for money.

Can you print multiple colors without screens?

Yes, digital printing makes it possible to print multiple colors without any screens. You can create photographic-quality designs, full-color images, and gradients without requiring multiple screens. You can print hundreds of colors in just one go because a digital printer applies ink using CMYK and also opts for additional inks for a versatile range.

In the case of screen printing, every new color will need a new screen, which increases the time and cost of setup and also adds limitations on the number of colors. Hence, screen printing is only practical if you need to use a maximum of 4 colors.

How does wash durability compare?

Screen printing is more durable compared to digital printing when it comes to repeated washing. Screen printing uses plastisol inks, which stay on the garment with a crack-resistant finish. For sports uniforms, work, wear, or washable apparel, screen printing is a better choice.

Digital water-based inks, which soak into fabric and create a soft feel. Although technological advancements have made these inks wash resistant, they still do not last as long as screen printing.

Are there any designs that screen print cannot achieve?

Yes, screen printing has design limitations, especially if you need detailed and fine textures and gradients. Every color is applied individually, and hence it is difficult to attain precision in this case.

Moreover, the color alignment for every layer of ink also gets harder to maintain if you introduce very complex designs in screen printing. Hence, high-resolution photographic images are very difficult to replicate in screen printing using traditional screens.

Digital printing can handle complex designs very well. The digital printers read digital files and hence produce complex pallets of colors, detailed designs, and even high-resolution graphics very easily. So, if you are a design photo-based artist and need photo-based artwork, you can go for digital printing to achieve the best results with fewer technicalities.

Is digital printing eco-friendly than screen printing?

In most cases, digital printing is more eco-friendly compared to screen printing, especially when it comes to small batch production. This process uses water-based inks, which don’t harm the environment. Whereas screen printing, at the same time, plastisol inks, which contain PVC, can be harmful to the environment.

DTG involves very minimal waste; you can use the ink only, and there is no need for cleaning the screens and disposing of excessive materials. Hence, it reduces the usage of water and also energy consumption, playing a positive role on the environment.

Screen printing is capable of using eco-friendly methods and inks, but uses a lot of water for washing screens and even ends up wasting ink, leading to chemical exposure. Although sustainable screen printing is possible, it needs additional materials and effort.

Hence, brands that prioritize sustainability must consider digital printing as it is aligned with eco-conscious values.

Conclusion

Choosing between screen printing vs digital printing process requires assessing a lot of factors, among which the use case and cost comparison play a vital role.

If you are looking to get a bulk order manufactured, then choosing screen printing can be economical, provided that your design is simple and the colors are limited. Whereas, if you plan to get a small quantity of custom orders printed, then choosing digital printing is a better choice.

Request a Quote: Custom Screen or Digital Prints for Your Brand

Do you need a high volume of printing done on different materials, or looking to get some samples customized? We at Tendee Accessory Shanghai Limited can help you get them printed through the right printing method. Our team assesses the product, colors, design, and your budget and chooses the option for you that is according to your preferences. So, get in touch with us today.